Whether you are an audiophile, music lover or a simple esthete, vinyl records are more than essential. Nothing beats the old, warm and atypical sound of a record placed on a turntable. However, right now, pressing vinyls presents a cost that is mostly inaccessible to developing artists. Not to mention the overproduction costs and inventory management issues. Therefore, here is a detailed guide showing you how to press your vinyls according to your needs, in an efficient and affordable way.

1. The vinyl craze is confirmed

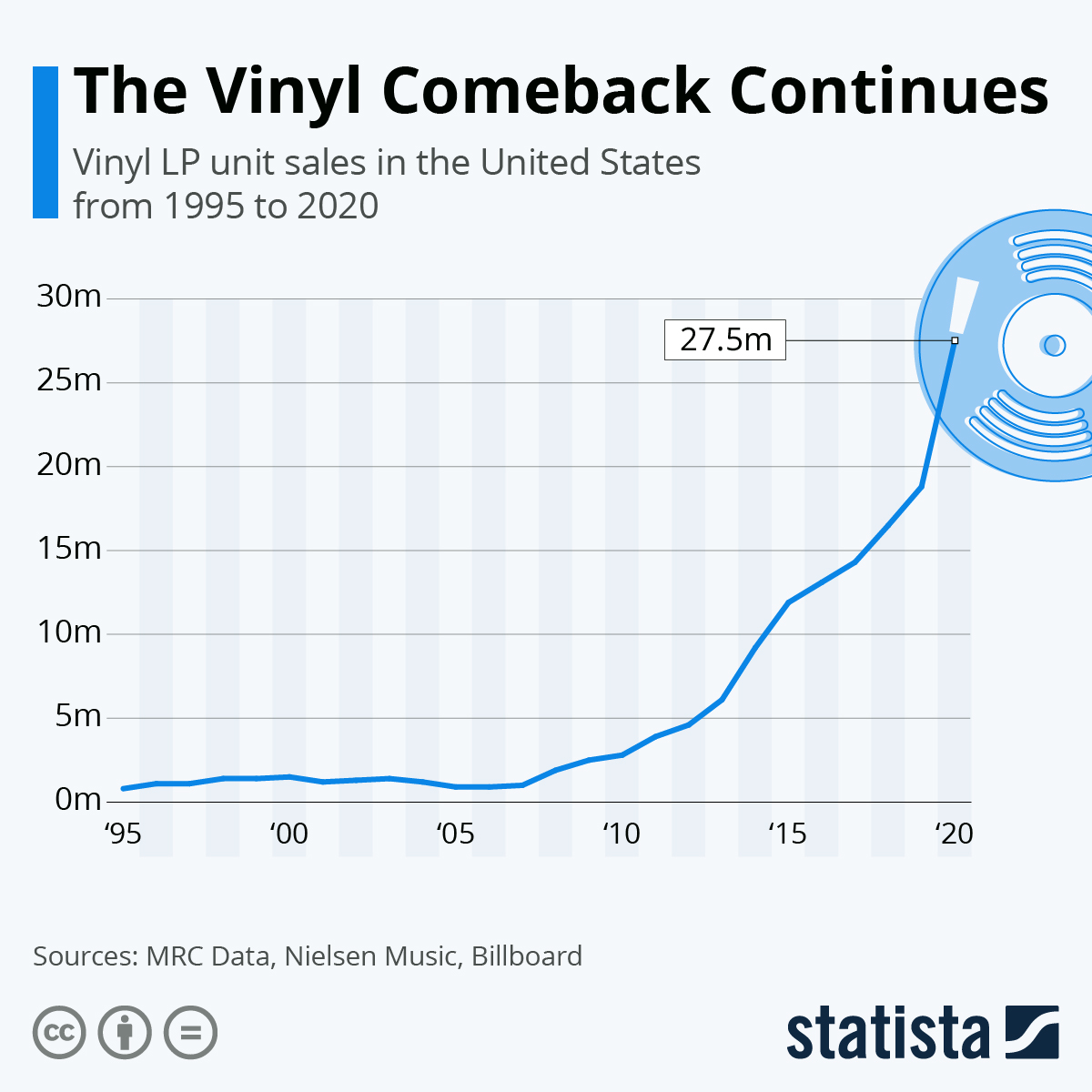

While the CD has struggled to resist the ascendancy of streaming over the past five years, the vinyl record is on the rise more than ever. Indeed, in 2020, 27.5 million LPs were sold in the United States, up 46 percent compared to 2019 and more than 30-fold compared to 2006 when the vinyl comeback began. These trends have been confirmed in 2020 by MRC Data’s 2020 Year-End Music report,. The public’s enthusiasm for vinyls over the past few years has not waned. This shows volumes and sales multiplied by five in the last five years and represents almost a fifth of physical sales.

The Vinyl Comeback – Vinyl LP unit sales in the United States from 1995 to 2020

Although the vast majority of sales come from the back catalog – Mickael Jackson, Amy Winehouse, Queen, Nirvana or Bob Marley, 25% of the top 50 are new artists – Johnny Hallyday obviously but also Lomepal, Orelsan, Eddy de Pretto , Jain or Taxi Therapy. Investing in a vinyl catalog can be a particularly good choice if you want to unite your community of fans.

| Check out : Instagram for Musicians: How to Gain New Followers in 2021

2. Prerequisites before pressing your vinyl

Before starting the process of pressing your vinyls, certain conditions are essential in order to have a quality result and a return on investment:

- You need to make sure you have a special mastering done by a sound engineer for a vinyl record (a CD mastering will render very poorly on vinyl). It is imperative to transmit a compressed file of RAR or ZIP type for each vinyl and clearly note the order and the side you want for your masters.

- Obtains a support production request via this online form (valid for both CD and vinyl).

- Assign an ISRC code for managing copyright.

- Ensure distribution and sales management by setting up a catalog number and a bar code.

- The design / graphics (selective varnish or other creative effects) of the possible cover and the badge (the graphic visual located in the center of the vinyl record) must be completed and transmitted before pressing. The cover is also a space of expression that is important, especially in the visual representation of the musical universe of an artist or a label. It is precisely this alliance between graphic art and sound performance that makes vinyl an unrivaled medium.

| Check out : 5 Mixing Tups and Tricks: How to Make Your Music Sound Good

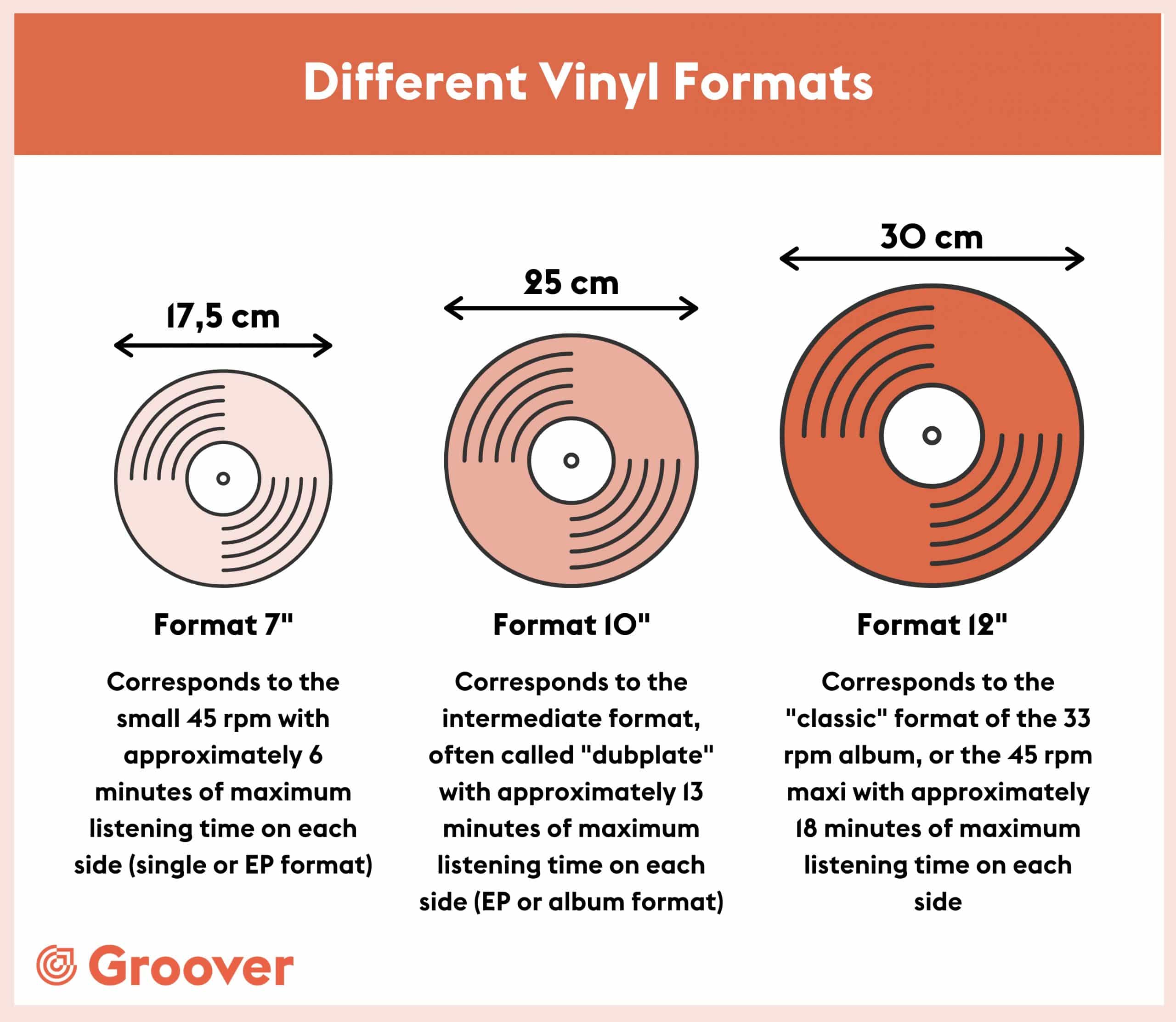

3. Know the different vinyl record formats

Depending on the length of your production (album, EP or single), your budget or simply because of your personal desire, there are several vinyl record formats.

5 essential tips to press your vinyl records efficiently and affordably

4. Know the different stages of vinyl record production

Pressing a vinyl is the work of a goldsmith. Although this step is relayed to a professional, it is imperative to have a good understanding of the different manufacturing steps in order to better understand what the cost of producing a vinyl record is based on.

- Cutting : Once the audio is mastered and transmitted, it will be “engraved” on a lacquer (aluminum plate covered with varnish) on which the signal will be transformed into vibrations. This step is performed consecutively on each side of the disc.

- Galvanization : Once the lacquer is engraved, it is then “galvanized”. The galvanizing process corresponds to the nickel bath in which the lacquer is kept for several hours. By electrolysis, nickel particles will attach to the lacquer and form what is called a matrix. This will then be fixed on a mold, ready for pressing.

- Pressing and pocketing : When the matrix is in place, it’s time to press your vinyls. This, placed on the mold, will be heated, pressed and then cooled for about 12 hours. After cutting off the excess material, the vinyl is immediately placed in an anti-static sleeve.

5. Press your vinyls in small series to minimize the risk of overproduction

Conventionally, vinyl records are pressed in series, with a minimum estimate of 200 copies. However, there are many alternatives available to press your own vinyl records individually (or in limited edition) with the same quality as the so-called “industrial” pressing. The vinyl pressing in small series responds to a very specific demand from self-produced artists. The advantage of having your own limited edition vinyls pressed is that you can minimize costs and get a return on your investment by avoiding the risk of overproduction. In particular, this allows you to evaluate your compositions with the public, to practice mixing or to test whether the mastering is adequate. The price for a disc may vary slightly from one service to another, but it depends in part on the total time to burn and the options chosen (color, weight, shape, material, etc.) Among the services that offer this alternative we have found: Diggers Factory (our partner), M Com’ Musique (price on estimate), Wolfpack (price on estimate), Confliktarts (our partner), Dubplate, MyVinyl.fr, GVU (Individual vinyl engraving) and Vinylogue.

| Check out : Radio: How to get your songs successfully on the air?

– Translated by Betty Gonzalez –